Bedroom Details

For my daughter’s bedroom, I wanted to do a couple of murals on the two largest opposing walls. The remaining walls would continue the neutral gray we would utilize throughout the main level.

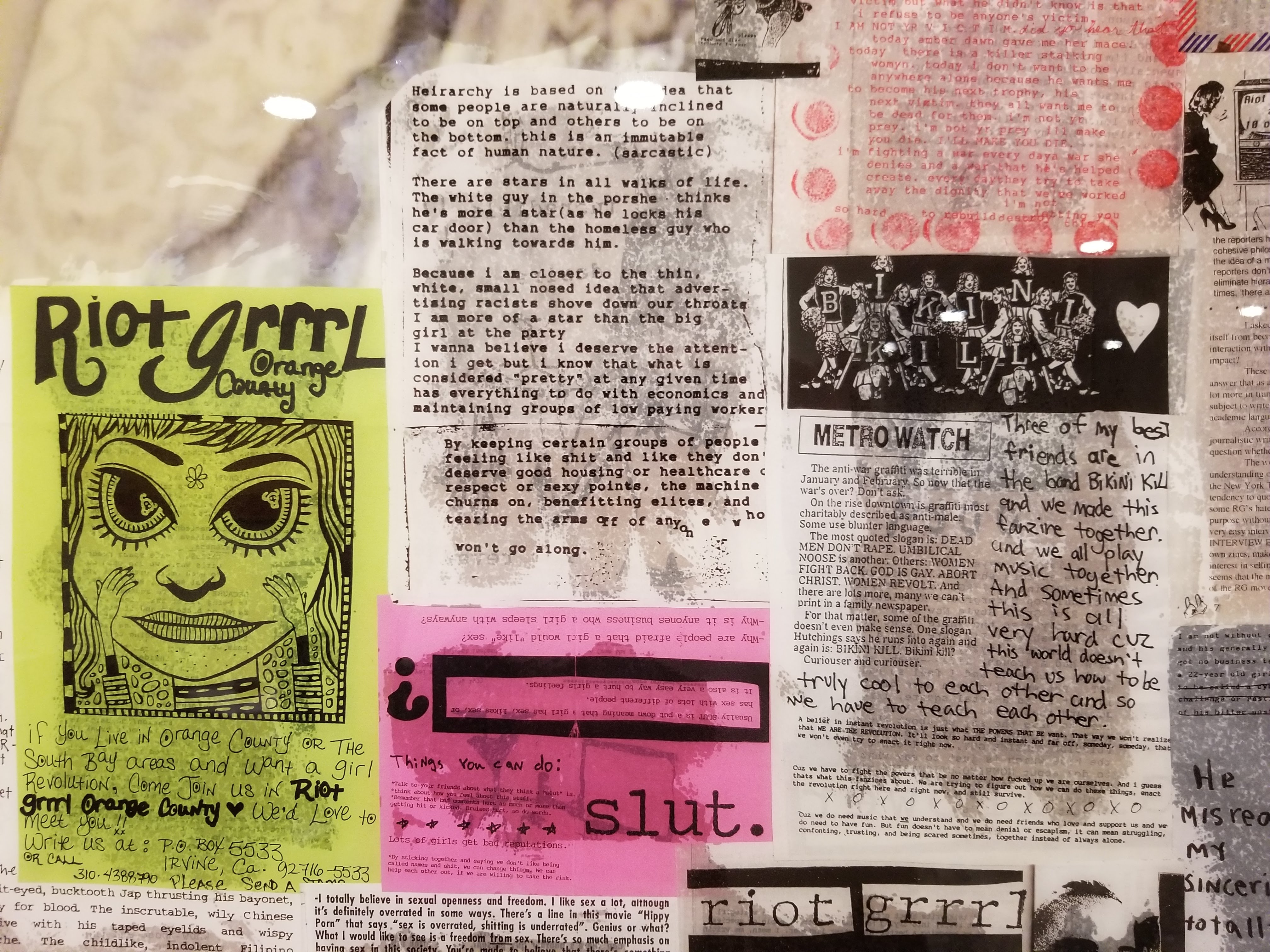

The first mural would be multi-colored, inspired by Eddie Van Halen’s Frankenstrat guitar:

Although I would change up some of the original colors, the overall layout would be roughly the same.

The mural started with a base coat of blue. Once this was dry, I applied painter’s tape to set up most of the striping that was based on the guitar:

With the tape in place, I could begin applying the finish coat of pink:

Once the two coats of pink were dry, I slowly pulled the painter’s tape to reveal the blue lines just below the surface:

The final step was setting up and painting the white stripes, including some ‘torn’ or ‘frayed’ ends:

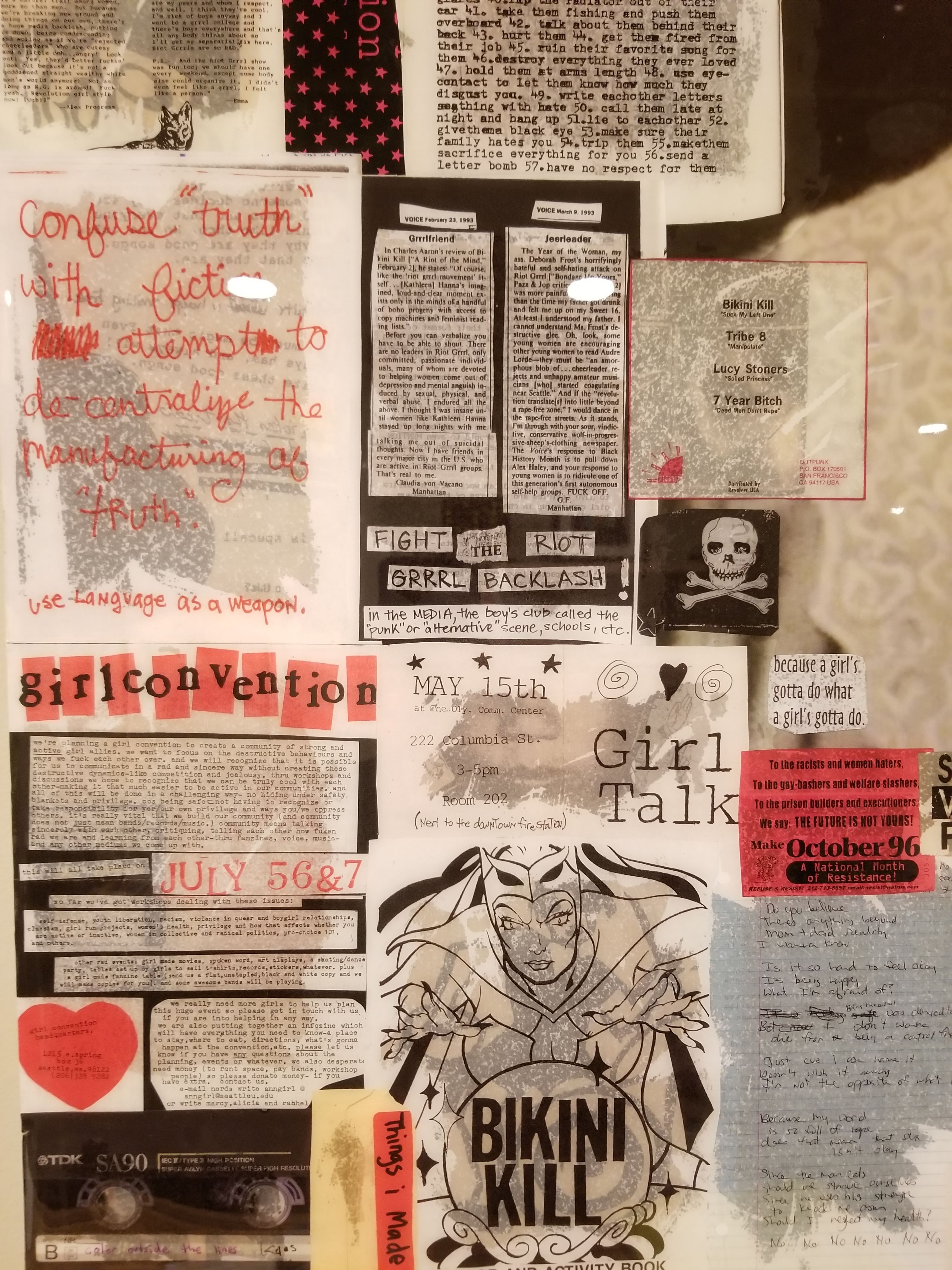

The second mural would be a more subdued, but stark, black and white color combination.

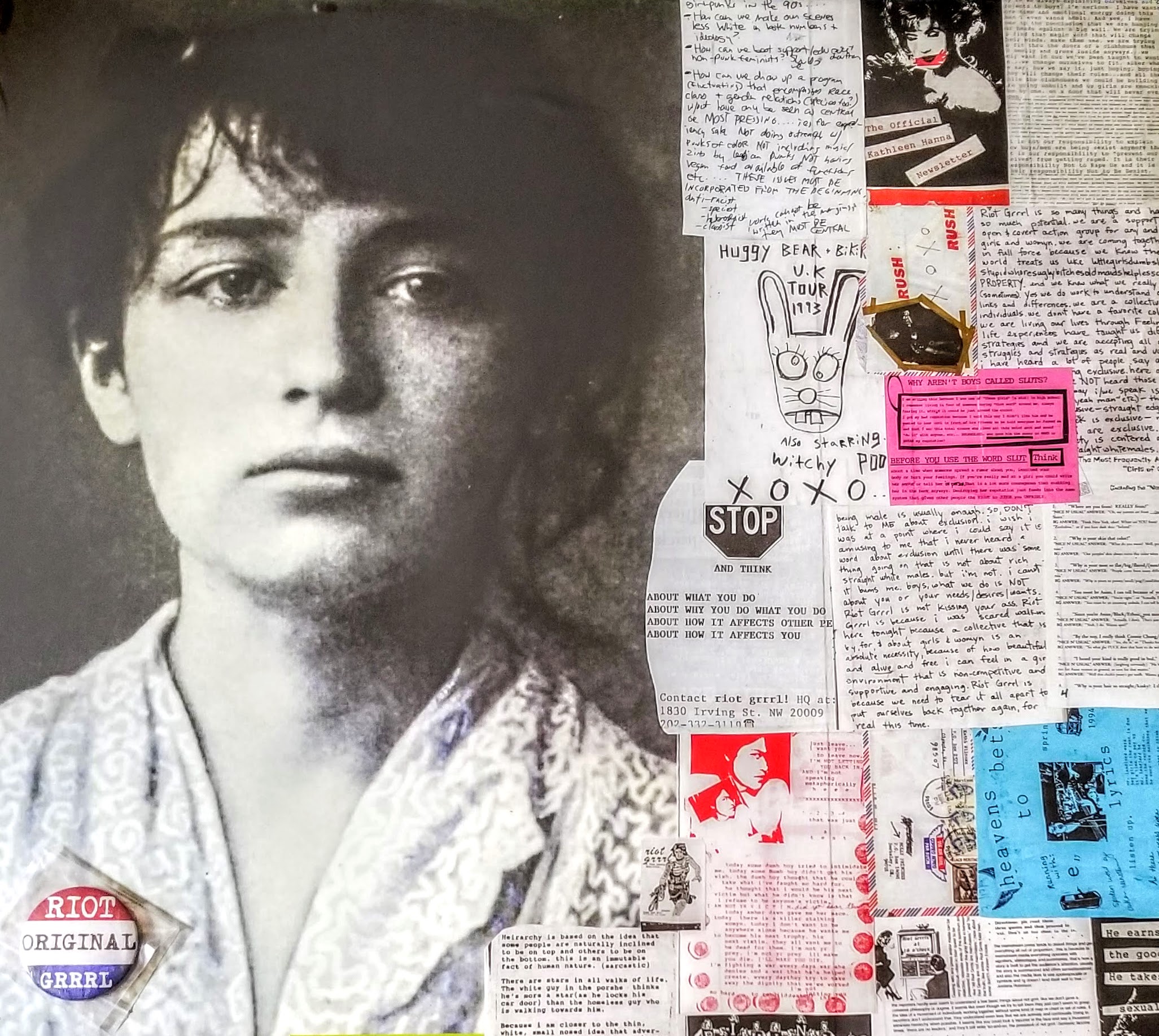

On this larger, opposing wall I wanted to try recontextualizing (i.e., appropriation) an iconic but infamous piece of graphic design. In this case, the World War II era Imperial Japanese flag (or Rising Sun flag), so it was important to undermine and invert the intent, or at least the associations, of the original design, rather than, for example, trying to undermine it with humor. In effect, steal some of the thunder inherent in the power of the original layout but for wildly different goals.

Much of the fascist iconography (in all its variations), while undeniably effective in terms of ‘branding‘ when it was on the rise during the WWII period, is also ripe for satire and deflation:

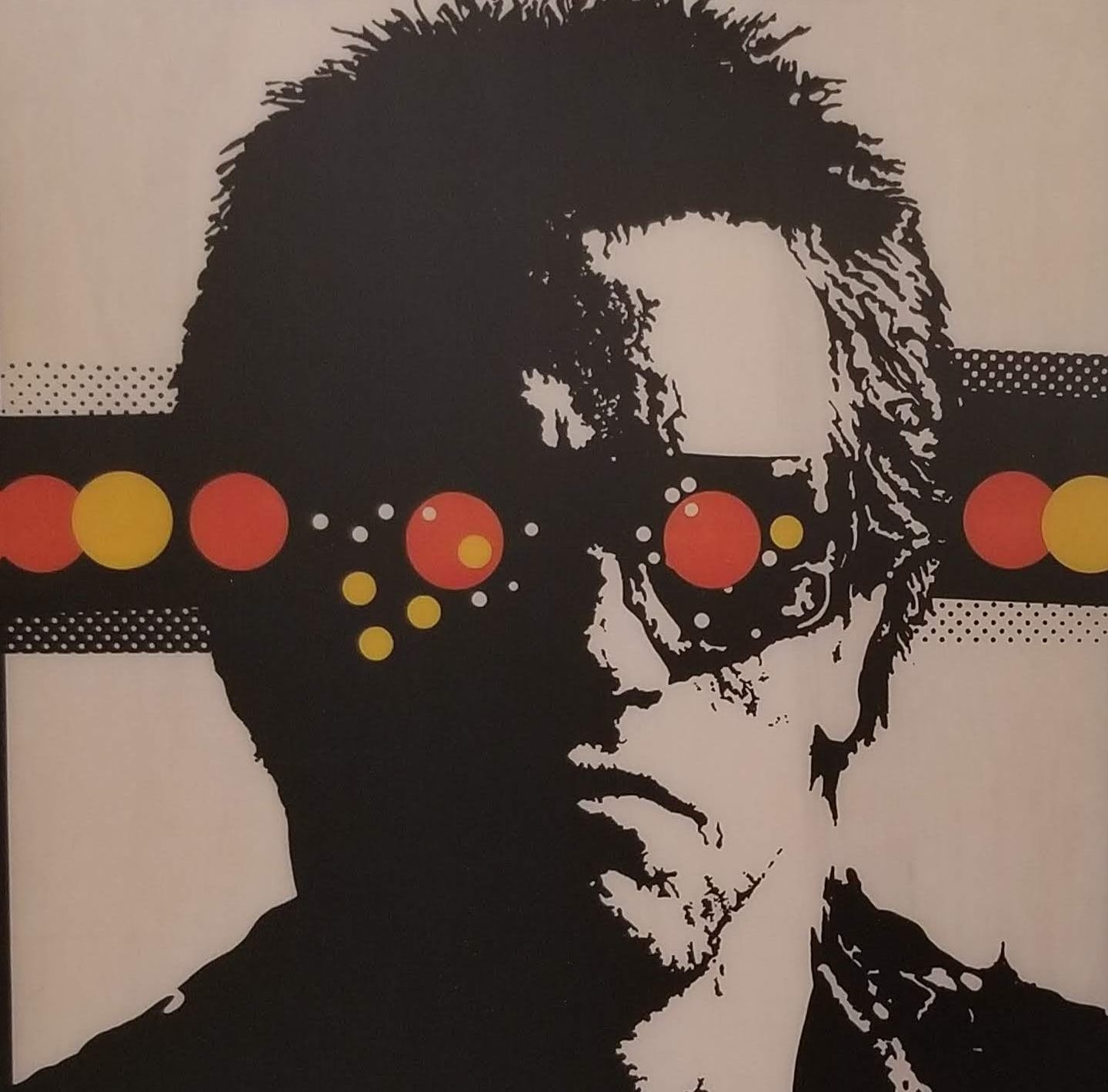

An American artist, Ron English, does an excellent job in this regard, similar to The Simpsons, when it comes to satirizing or ridiculing marketing and pop culture icons and logos:

Where the original Rising Sun flag personified a ‘might makes right’ ideology, one rooted in racist ideas about cultural superiority, I wanted to undermine this ‘logic’ without losing the visual impact of the original design.

Alongside Imperial Japan, Nazi Germany, of course, produced some of the most notorious symbols and imagery of the WWII era (the power of these symbols and images resonates to this day, showing up in some pretty unlikely places):

In terms of the Rising Sun flag, the power of the design begins and ends with the circle or disc at its center.

“If the square is bound up with man and his works, with architecture, harmonious structures, writing and so on, the circle is related to the divine.”

— Bruno Munari, Design as Art

In addition, the 16 equally sized bars or ‘sun rays’ in the original only strengthen the effect, encouraging our eye to land on and remain focused on the red disc.

“The eye is attracted by the dark disc and has no way of escaping. It has to tear itself away… The eye is in fact accustomed to making its escape at the points or corners of things, at the head of an arrow for example. A triangle offers three escape routes, a square offers four. A circle has no corners, and the eye is forced to go round and round in it until it tears itself away with an effort.”

— Bruno Munari, Design as Art

A twisted irony considering that this rising sun motif (traditionally a sign of hope, e.g., marking the end of bad times) is so strongly associated with the darkest period in Japanese history.

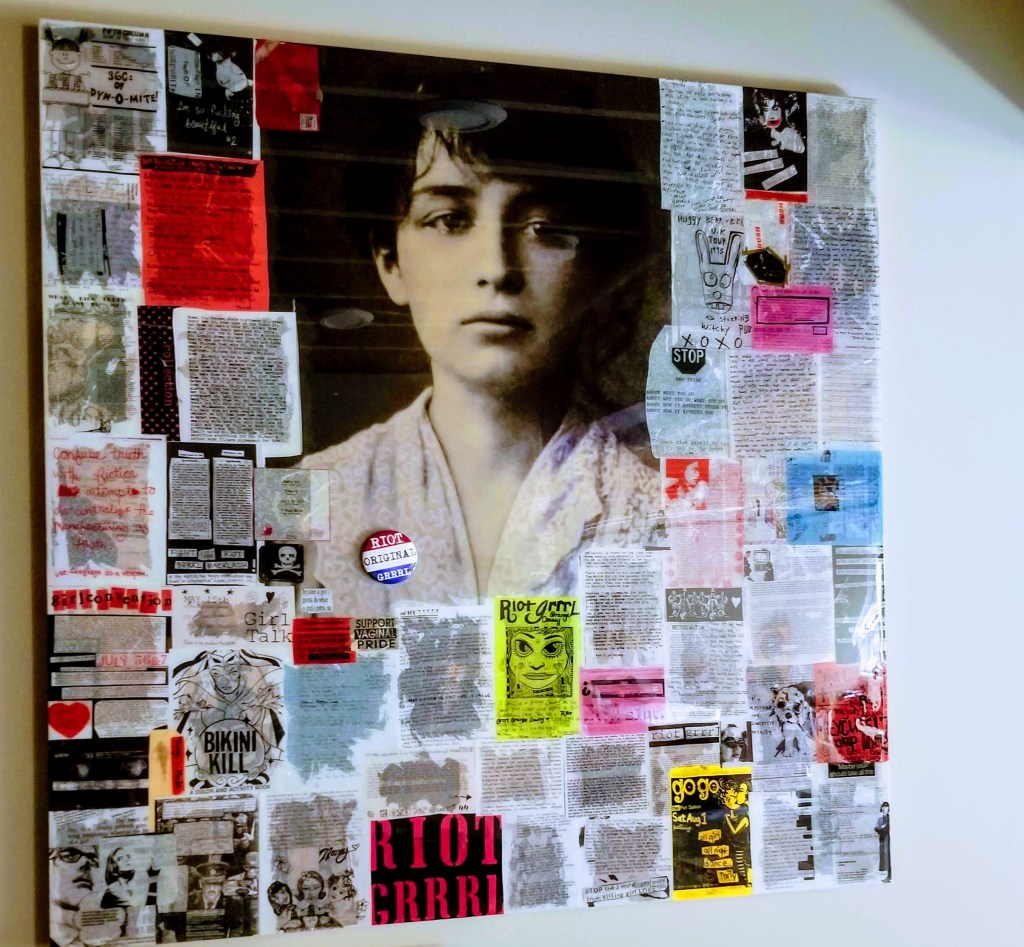

With a base coat of pure white, the black circle, after being laid out in pencil, was handpainted. When dry, I then laid out the black sun rays using blue painter’s tape to establish the exact thicknesses and angles:

Instead of using the red and white combination, I chose to go with a more stark, even absolute, color combination of black and white (i.e., all of the colors combined with an absence of color). Additionally, I broke up the 16 ‘sun rays’ into only 12, while also playing around with their individual sizes, ensuring variation in the final layout. In a similar way, the intent was to reflect the difference between a square (fascist overtones, man-made) and a circle (divine, natural). Where the original 16 uniformly sized and spaced ‘sun rays’ suggest conformity and submission of the individual to a system of authority, rooted in strict hierarchy (e.g., the sun, like the Emperor, at the center of power), having fewer, thicker ‘sun rays’ in various sizes suggests not just imperfection but also playfulness, while hopefully retaining much of the power in the original design. Because of the wall layout, it also meant more variation in the length of the individual ‘rays’, particularly having one spill across the door opening to the walk-in closet, even ‘ending up’ on the back wall of the closet where it helps to set-off a framed series of portraits:

Since so much of the Fascist movement utilized language to achieve its aims, especially in the use of sloganeering and euphemisms, the black circle seemed the ideal spot for the placement of some poetic language. My daughter helped me stencil in a line over the ‘black sun’ from a Bruce Cockburn lyric, which is quoted in a U2 song:

Repeating the logic of the ‘imperfect’ sun rays, the layout of individual letters was intended to highlight their fragility — some opaque, some appearing slightly faded, running above and below an invisible line — as if struggling to stay on the wall.

Having a vivid mural near a doorway definitely makes for a strong visual statement:

We let the black ‘spill over’ into the walk-in closet as an accent wall — a stark background for some framed superhero portraits:

With the two murals complete, I could turn my attention to making some new furniture pieces, including a bedframe and a dresser.

For the bedframe, I utilized framing members (sticking with our Urban Rustic theme), including 2×6’s, 2×4’s, and the 1×4 furring strips:

Keeping the wood natural, combined with lag bolts in the corners, I finished off the bed frame with some racing stripe hash marks and our daughter’s nickname stenciled on the side:

With the bed frame in place, I added a bunch of throw pillows with interesting designs or patterns along the two interior walls:

After our extended build, which included a few moves along the way, it was finally time to come up with at least a semi-permanent dresser for my daughter.

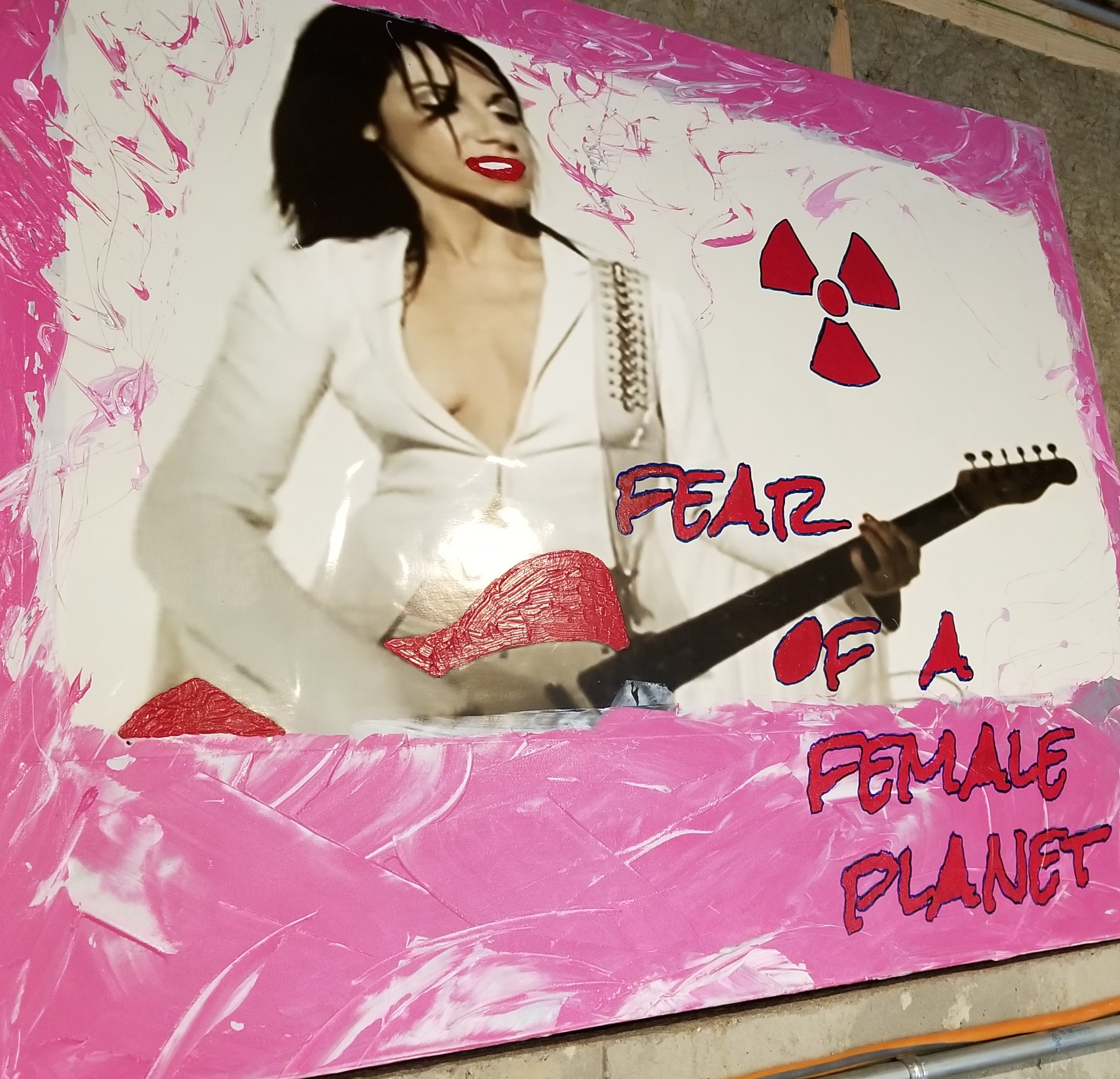

Wanting to keep things playful (as opposed to formal), it seemed like a good opportunity to do something over the top, for instance, using bold colors while having it be oversized in terms of its structure and footprint.

In the photos below, the initial carcass and then the drawers being put together. I decided to go with deep, overlay drawers to maximize the opportunity for storing bulky items like sweaters, hoodies, and jeans. I also just liked the proportions:

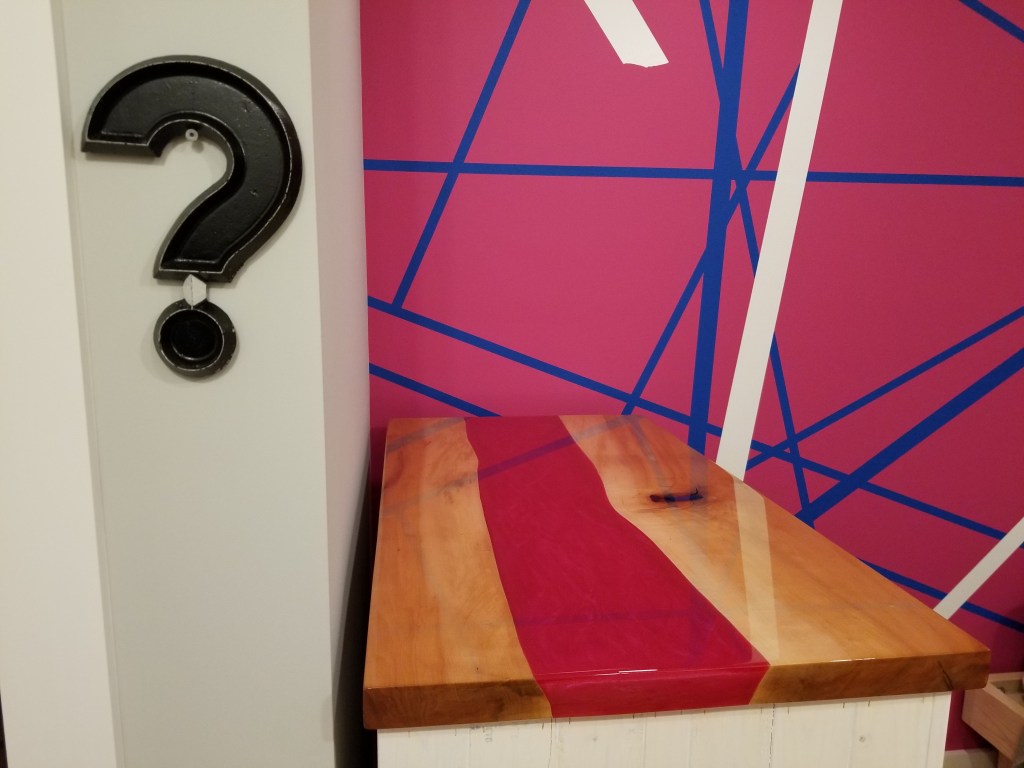

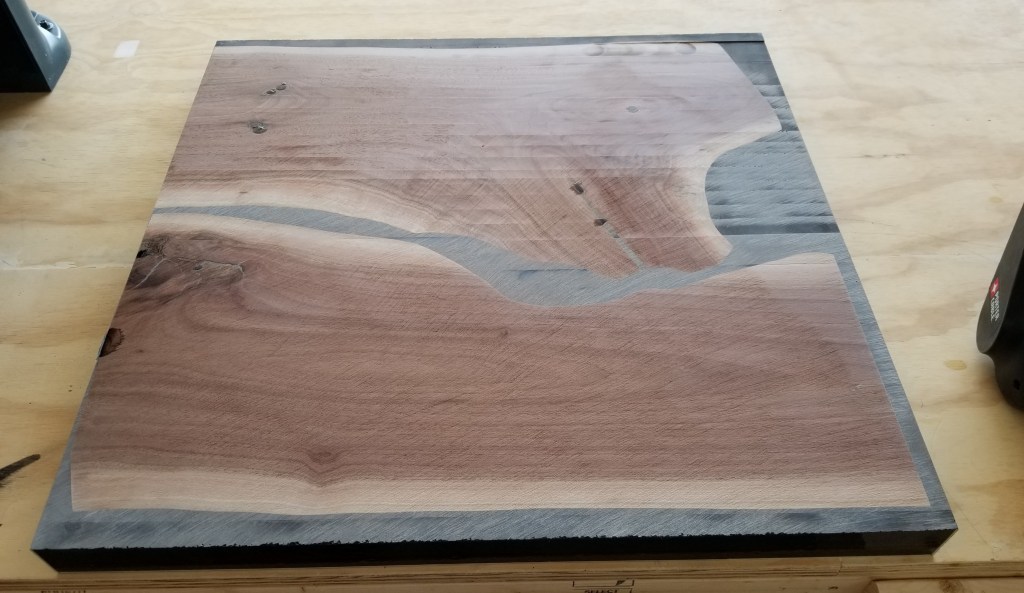

For the top, I found a couple pieces of mostly clear hickory, which was combined with a deep pour epoxy in a bright pink ‘river’ table top:

I tried to incorporate as many decorative swirls in the pink epoxy as possible, giving it a slight retro hot rod flame look:

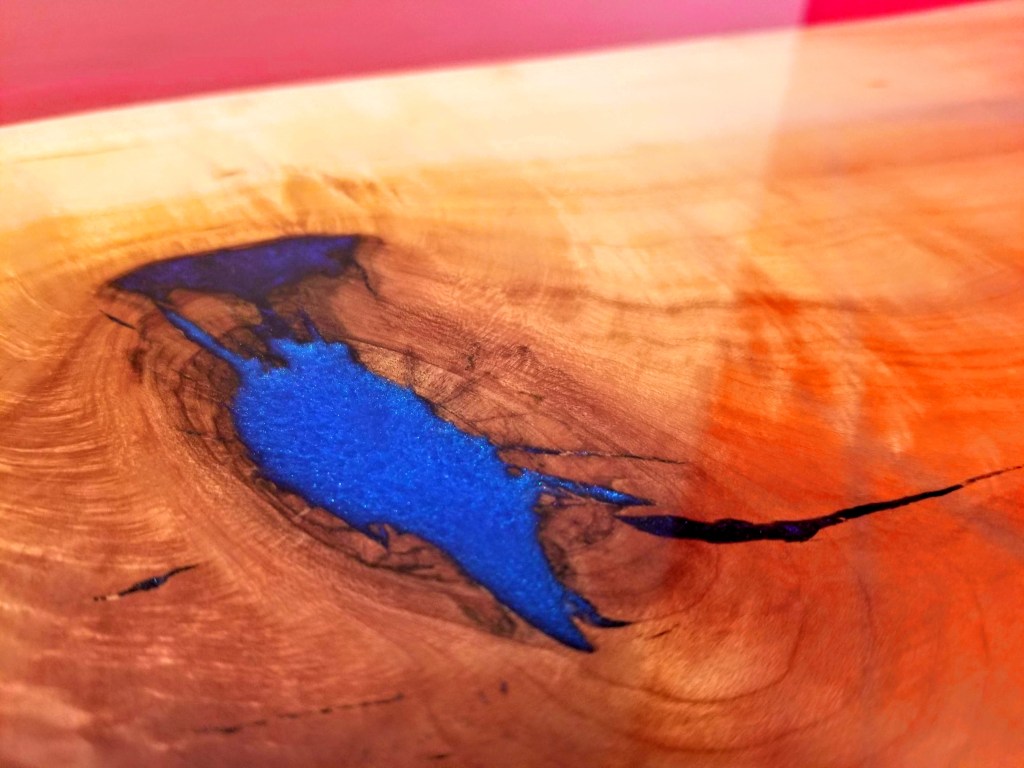

We kept a high gloss finish, which seemed in keeping with the child-like quality we were aiming for. In addition, although the hickory was mostly clear in terms of the wood grain, there was one large knot that allowed us to incorporate a couple of bright metallic blues:

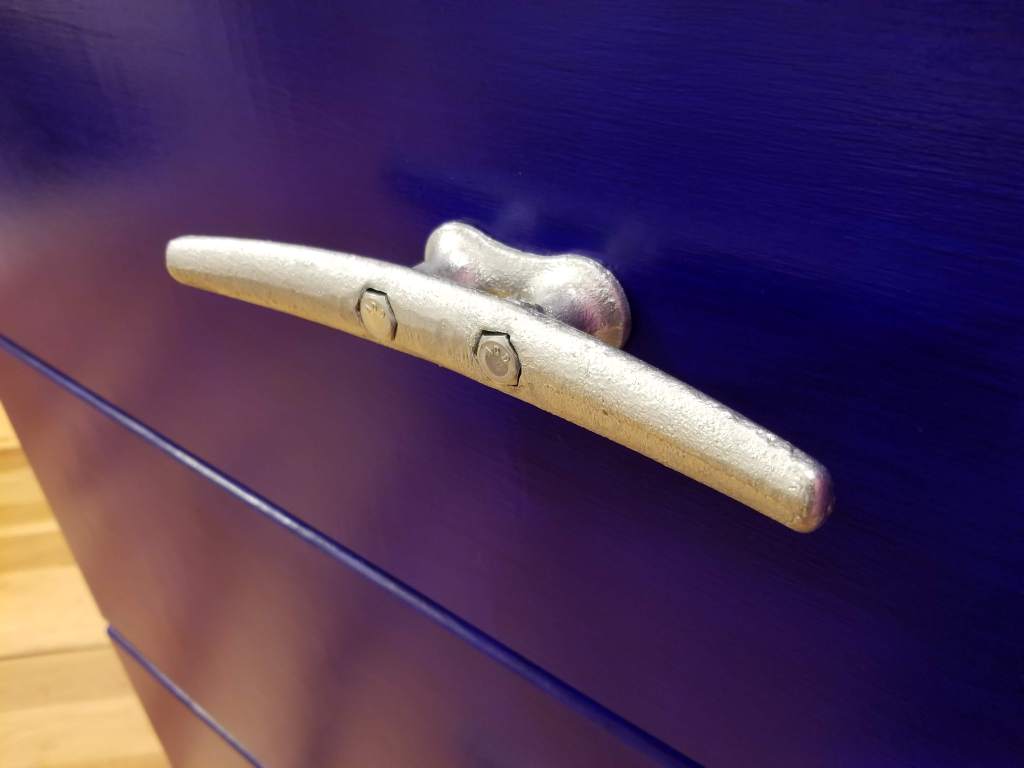

Oversized dock cleats were used for the drawer pulls, which are surprisingly ergonomic in terms of daily use:

The bright pink epoxy reminds me of hard candy like Jolly Rancher pieces with their preternatural shine:

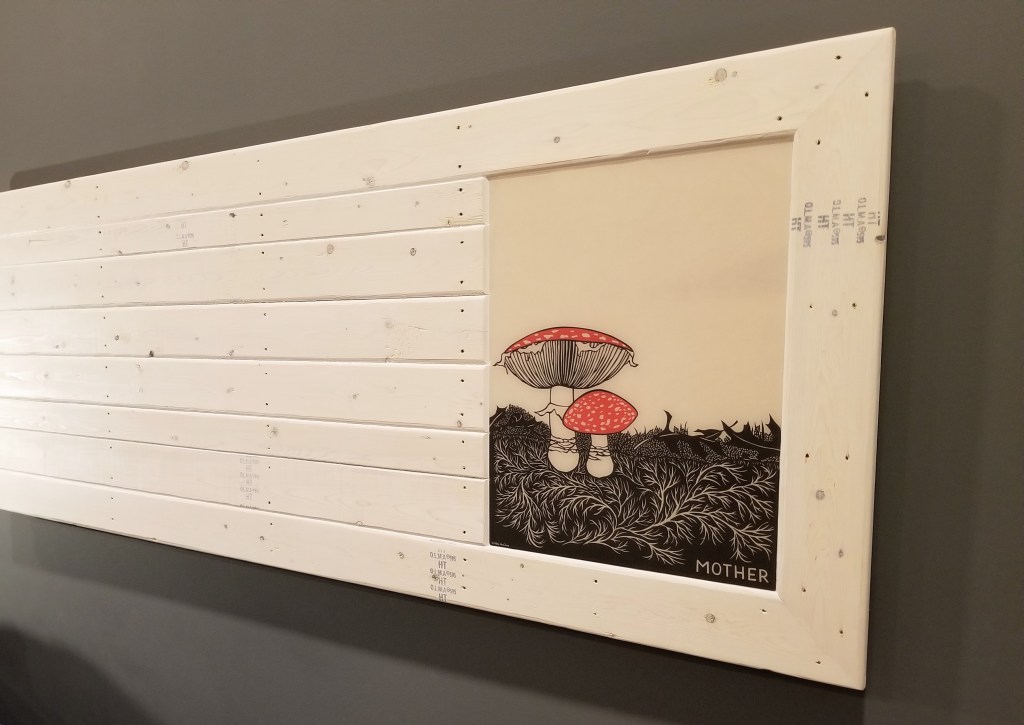

The whitewashed 1×4 furring strips serve as a rustic visual counterpoint to the more over the top epoxy:

The blue on the drawer fronts consisted of a couple coats of thinned paint, which produced a nice water-like blue effect. The paint was then protected with a couple coats of Osmo Poly:

The pink, blue, and white of the dresser were also a nice visual echo of the Van Halen mural:

Some of my online Urban Rustic finds ended up in the bedroom, including the vintage theater marquee question mark (above), along with a ‘Chicago’ eye bolt welded to an oversized nut used as a doorstop:

The bedroom door itself utilized some leftover 2×6’s from framing, pocket screwed together. The bright, vertical pink stripe continues the ‘racing stripe’ motif that began with the siding. The door handle matches our Roto window and door hardware. With only two real doors in the whole house, apart from our two exterior doors, it seemed like a nice touch to be able to maintain the same aesthetic throughout:

When the door is closed, the vertical stripe, especially next to the blue accent wall and the large, black barn door, makes for a bold, pleasing collection of design elements:

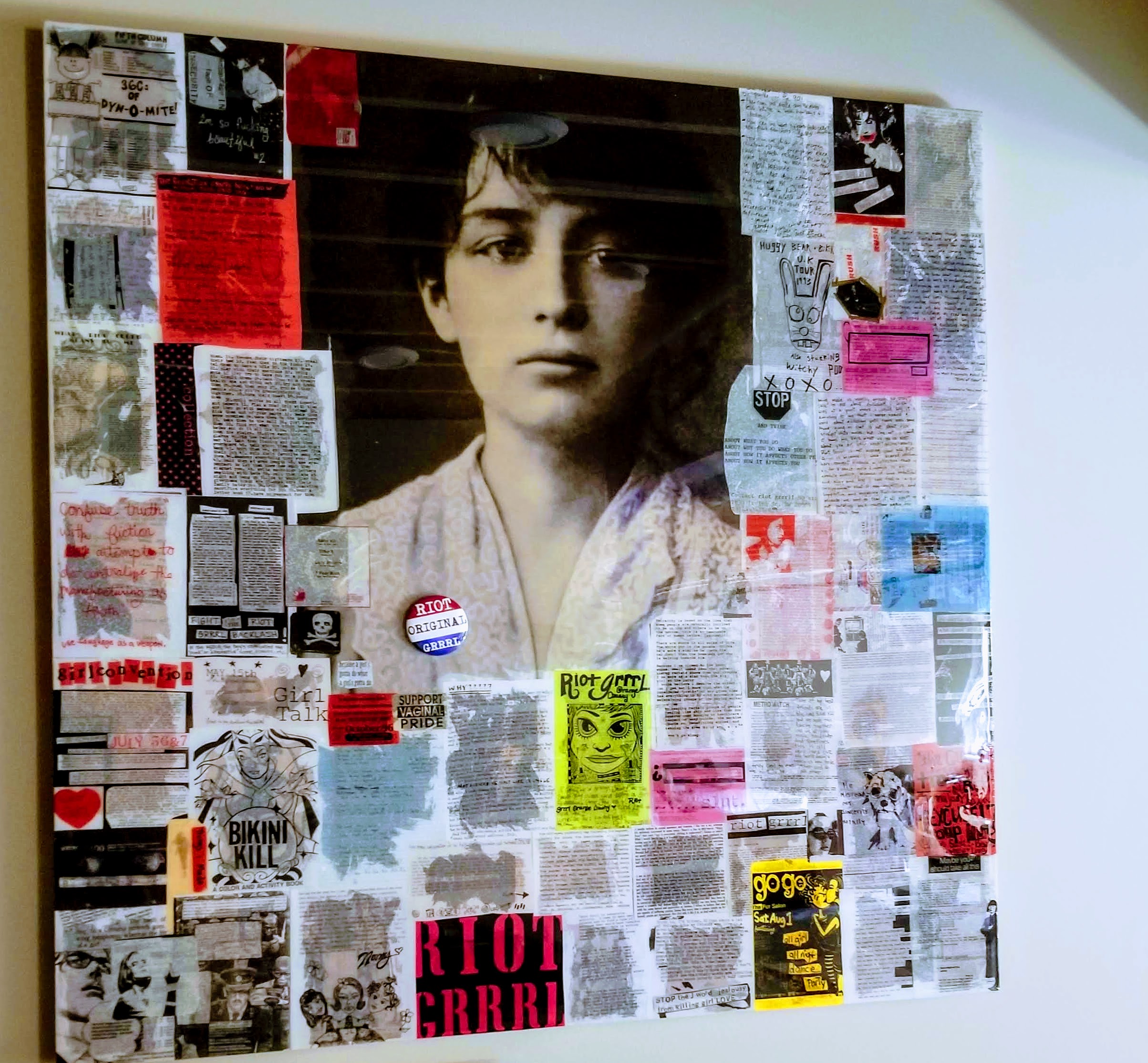

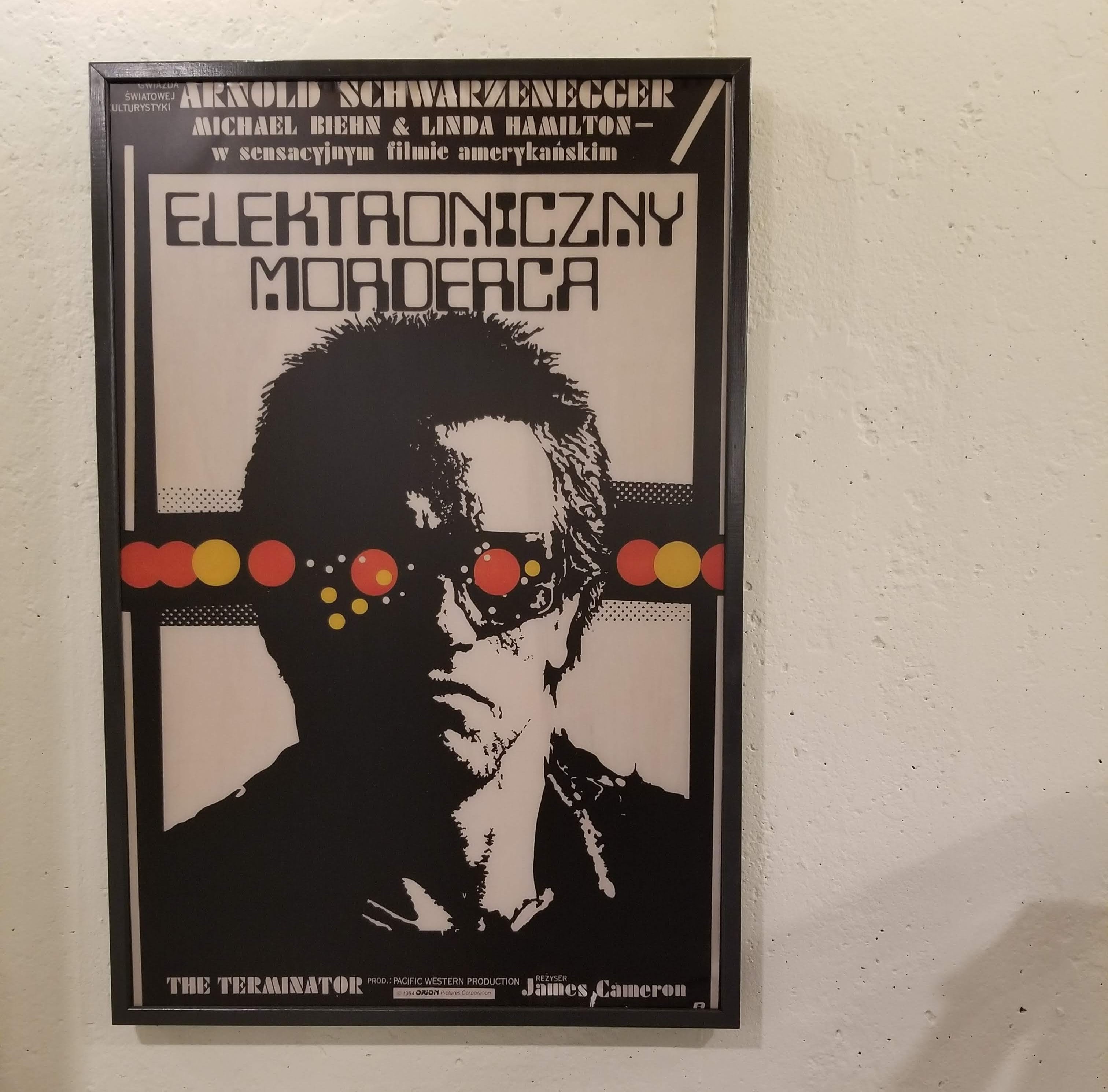

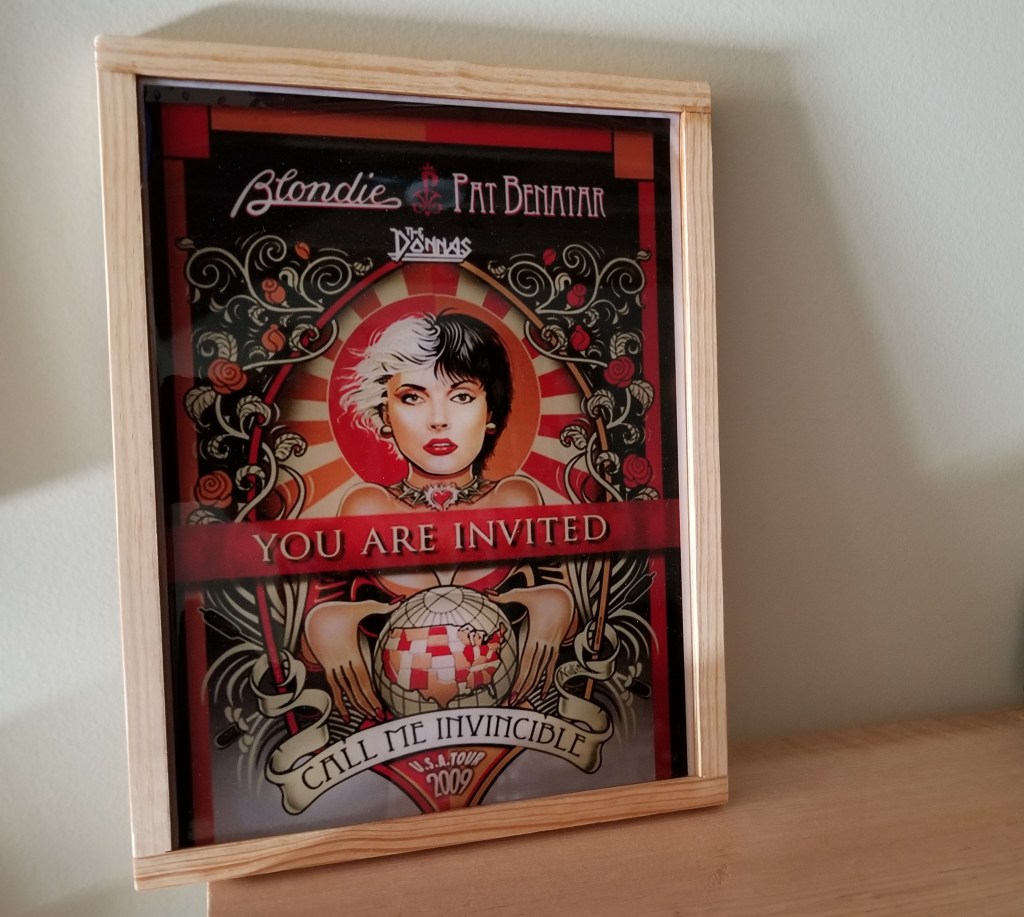

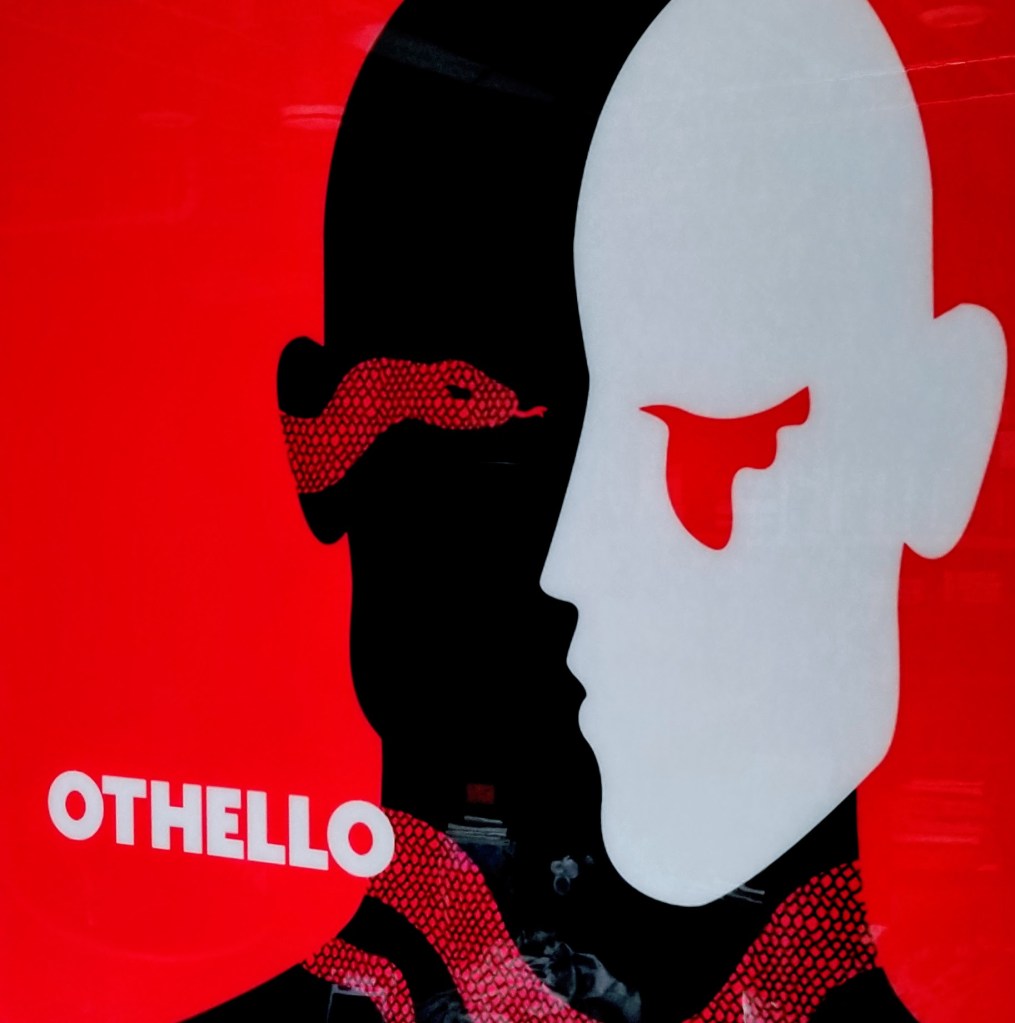

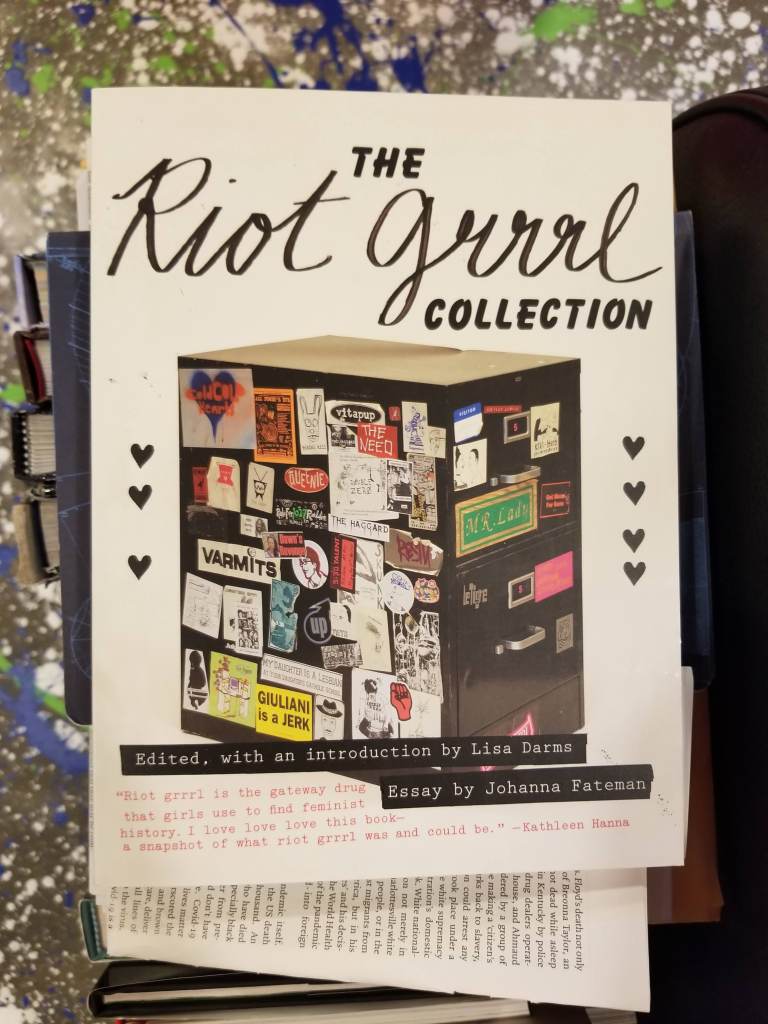

I also sprinkled in some smaller framed art pieces, combining visuals with text.

“It is far more fascinating to come into a room which is the living expression of a person, or a group of people, so that you can see their lives, their histories, their inclinations, displayed in manifest form around the walls, in the furniture, on the shelves. Beside such experience — and it is as ordinary as the grass — the artificial scene-making of ‘modern decor’ is totally bankrupt.”

— Christopher Alexander, et al., A Pattern Language

Below, a framed set of Ani Difranco lyrics is paired with a vintage railroad signaling light:

The black “LOVE” epoxy was added to the mix sometime later:

The black epoxy is a nod to an underrated Afghan Whigs album:

After letting my daughter create a painting using red, pink, and silver pigments, we dropped her blue-covered hand onto the canvas as a fun, messy way to mark the passage of time:

In the walk-in closet, for storage we went with a combination of 2×10’s and gas pipe for some open shelving. We would utilize this combination elsewhere on the main floor — including a linen closet, the pantry, and even in our kitchen. Sometimes we would use 2×8’s, depending on the items being stored on the open shelving:

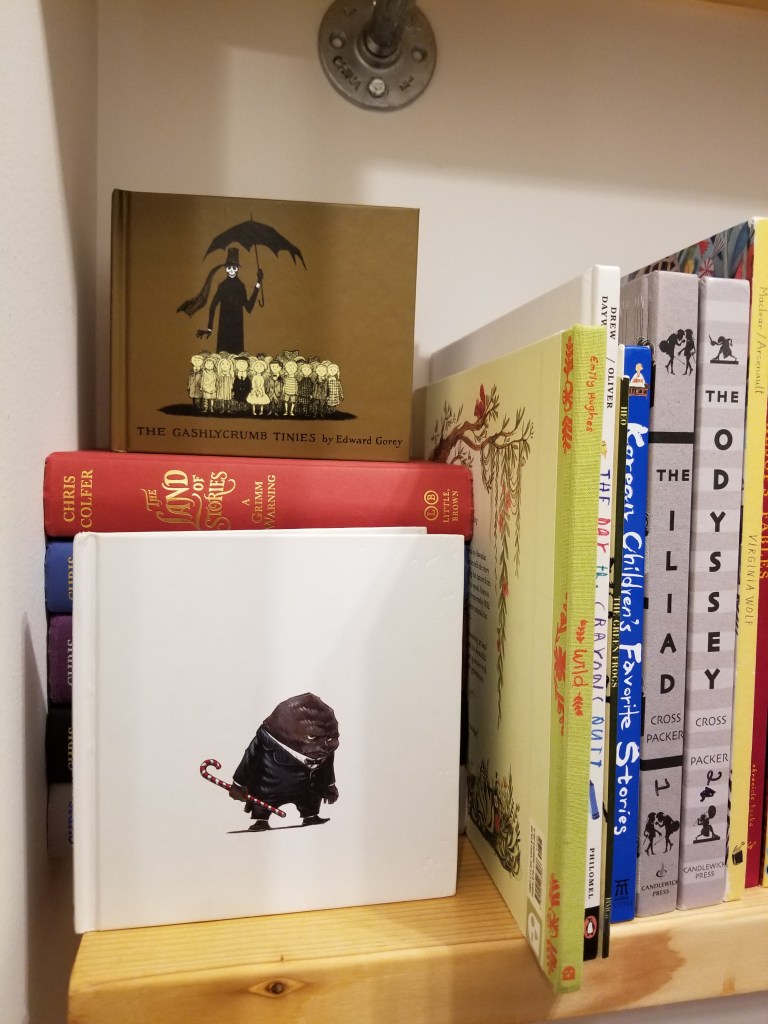

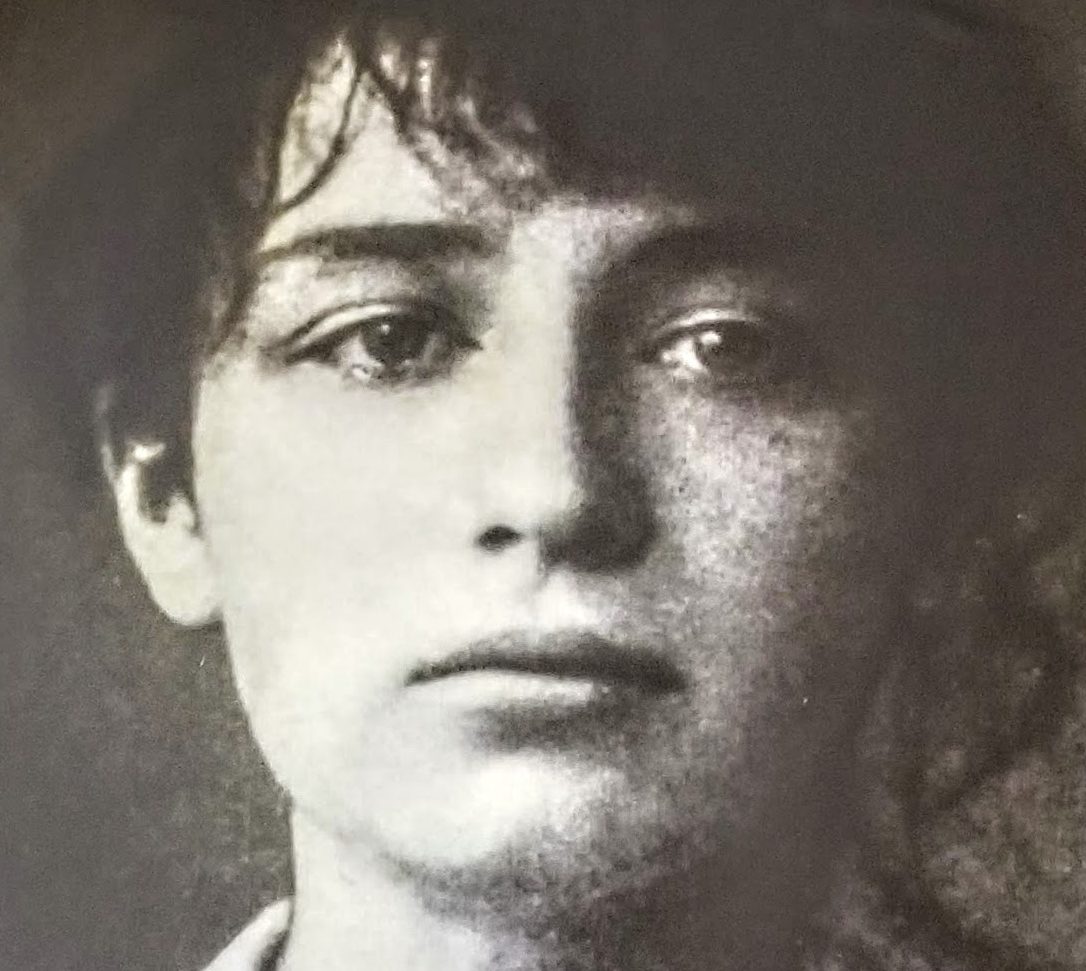

The open shelves were an excellent place to store books, board games, as well as a spot to sneak in some more artwork:

The Björk piece was inspired by this performance:

In order to use clothes hangers, I also added an industrial looking clothes bar:

To keep my daughter’s jewelry contained, but also easy to access, I made a storage spot out of a glove factory hand mold, painted black and mounted on a decorative concrete base. The base, made with Buddy Rhodes concrete, is accented with red decorative glass. While the top is polished, to bring out the shine in the glass, the bottom and outside edges were left raw to emphasize the difference in final finish.

Using another piece picked up from Great Lakes Yard, I created a bench for just inside the bedroom. A convenient spot for books, homework, or the next day’s outfit. In an effort to hold onto its original roughness, much like the piece in our main bedroom, I only lightly sanded before patching nicks, gouges, and other damage with black and silver epoxy. Also matching the dresser top, a flood coat of clear epoxy is the final, durable high-gloss finish:

Close-up look at a damaged area, filled with metallic silver epoxy prior to the flood coat:

Bathroom Details

In this second bathroom, we opted for white hexagon tile for the floors, including inside the shower. For the shower walls, we used vertically oriented oversized white subway tile with blue glass accents.

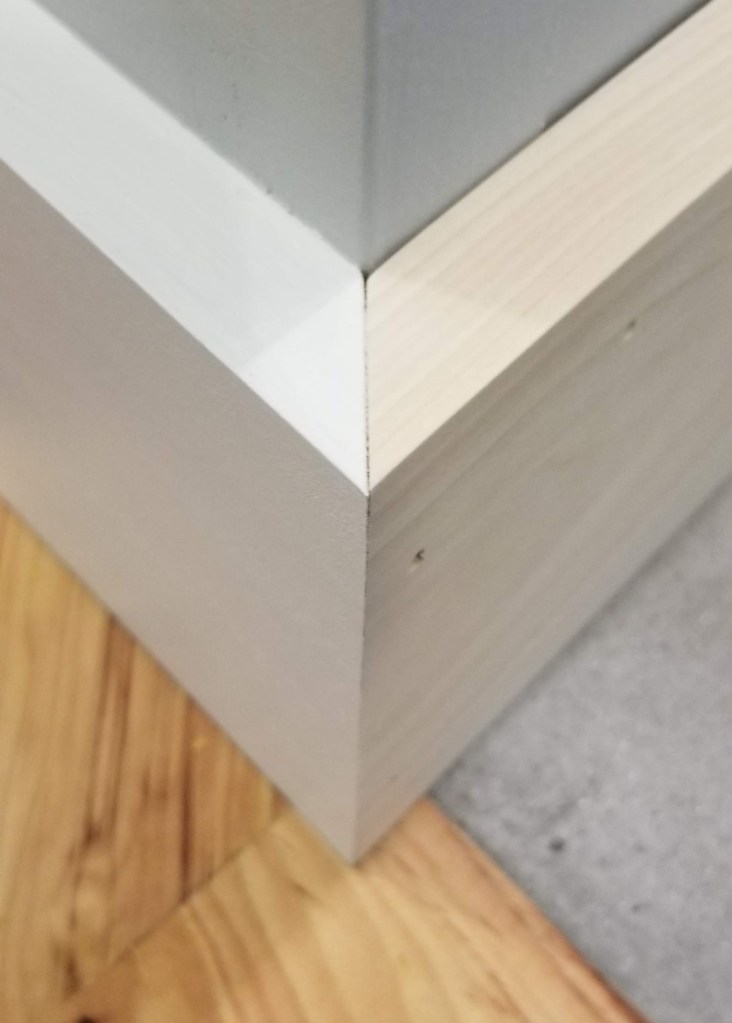

Matching the main bathroom, I repeated the use of our charred cedar with lag bolts and washers, combined with a vessel sink and our quartz countertops. With a vessel sink, the taller backsplash helps to keep excess water off the walls. We also continued with our 1×6 poplar base and 1×4 poplar door casing here in the bathroom area.

The bathroom starts with our base gray color for most of the walls — except for two walls, one directly in the bathroom; the second, making the transition to the bedroom. Here, our basement floor combination of blue and green shows up again:

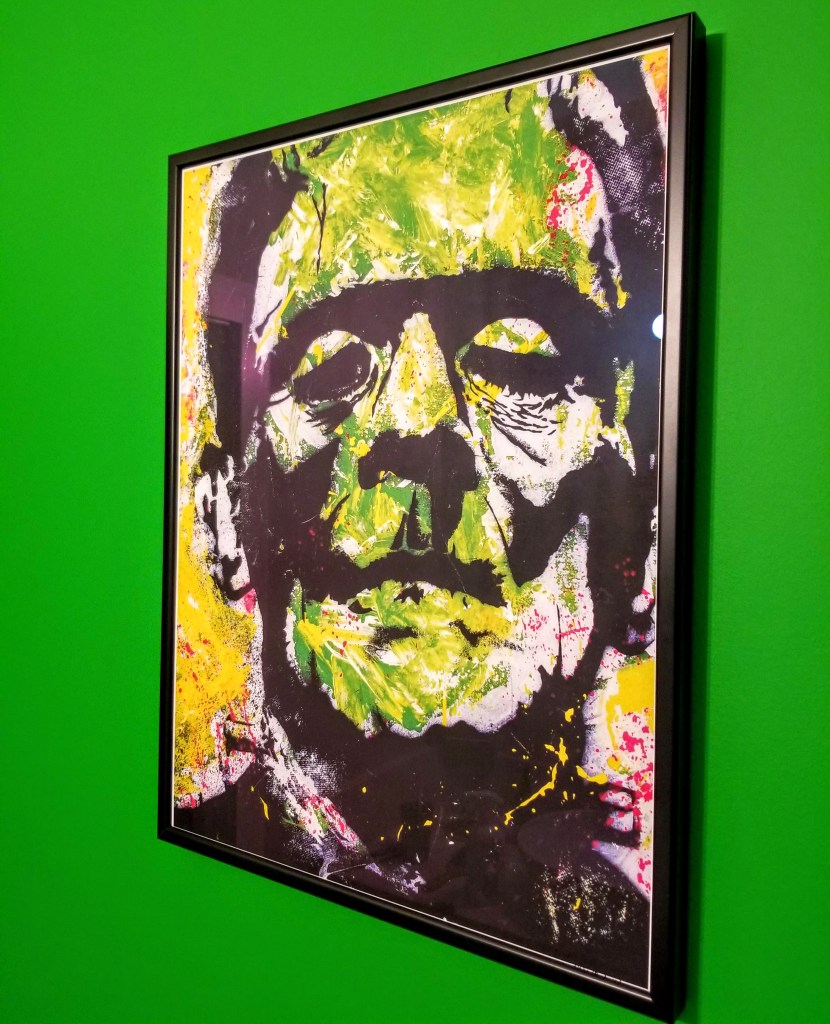

Heading into the bathroom area from the main living area (kitchen and family room), our monster theme begins with a portrait of Dracula, based on the original Bela Lugosi portrayal (the joke here with the monster theme is that nothing good happens in bathrooms — the sights, the smells, the shaving, the plucking, the scrubbing, etc.).

Instead of relying on vintage, original posters, or even stills from these classic movies, I opted for portraits that had a more modern take on these iconic creatures. It also marked a fun transition, incorporating one of my daughter’s nicknames, from bathroom to bedroom:

It’s a whimsical, detailed portrait of one of the great movie monsters:

I love the vivid pinks and reds in this King Kong poster:

Above and behind the toilet seemed an ideal, menacing perch for Lon Chaney Jr.’s Wolfman:

This modern, graffiti-inspired take on Boris Karloff’s iconic Frankenstein’s monster is rich in colorful details:

An added touch was positioning him on the green accent wall so that he’s clearly visible in the mirror above the sink, which, with its delicate butterflies, hints at the tragic lakeside scene with the little girl and her flowers from the classic James Whale movie:

For those at the sink who take notice, the monster is watching their every move:

For the bathroom door, I repeated the bedroom door’s use of 2×6’s, pocket screwed together, painted white, with a racing stripe. I also used the same door handle, once again mimicking the Roto hardware on our windows and doors, while also adding a cute, but also highly functional, Schlage VACANT/ IN USE deadbolt lock:

When we were collecting design elements for our house in the pre-construction phase back in 2015, these were just starting to show up in restaurant bathrooms in our area. They seemed equally useful in a residential setting:

Instead of using a screwed-on door stop attached to the baseboard, the bottom of the door, or even the floor, this colorful bag of coffee does the same job admirably with a nice pop of color:

For a toilet paper holder, I opted again for a custom-made option — pared down, sleek, and functional:

Exiting the kitchen, on the way to the bathroom, reveals a linen closet area. Here, I again opted for open shelving, with 2×10’s and gas pipe. The advantage of the open shelving is always knowing what you have and when to order or buy more. The downside, of course, is that there’s no place to hide from dust and clutter if things are allowed to get out of hand.

The ‘Crap’ and ‘Fur’ decorative boxes help contain the worst clutter-prone items — miscellaneous medicines, first-aid products, and hair care tools:

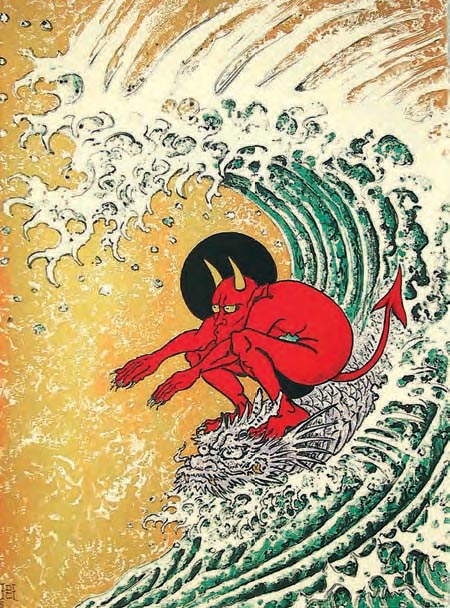

One final monster, just to the left of the bathroom sink, started with an Ed Hardy poster (n.b., Art for Life is a beautifully illustrated overview of his work in tattoos and on canvas):

His ‘Surf or Die’ piece captures the energy and playfulness I was after with our monster theme:

Using the same finishing process as the artwork in our main bedroom and in our basement, I mounted the image first on plywood before later doing an epoxy flood coat.

“… what we call a home is merely any place that succeeds in making more consistently available to us the important truths which the wider world ignores, or which our distracted and irresolute selves have trouble holding on to.

As we write, so we build: to keep a record of what matters to us.”

— Alain de Botton, The Architecture of Happiness

Since it’s so close to water at the sink (and things like toothpaste spray), I decided to leave it with a high gloss finish for easy clean-up:

In addition to the colors in Hardy’s painting complementing the colorful butterflies surrounding the mirror, the painting itself is a nice surprise for first-time visitors as they exit the bathroom.

You must be logged in to post a comment.