Top of Wall and Roof Connection

Once the wall assembly details were figured out, and our ceiling set-up detailed, the transition between the two became the next challenge. In other words, how to carry the air barrier over the top of our exterior walls.

I found this helpful article by Chris Corson from The Journal of Light Construction:

An Affordable-Passive-House (pdf)

Using a waterproof peel-and-stick membrane to wrap over the top of the wall (going from exterior sheathing — in our case 7/16″ Zip sheathing — to interior side of the top plates) seemed like the easiest way to maintain a continuous air barrier at the wall-to-roof junction. The membrane would also have a nice air sealing gasket effect after the trusses were set in place.

I also found this excellent Hammer and Hand video on YouTube (one of their many helpful videos):

Wall-to-Roof Air Barrier

Also, by being able to carry the Zip sheathing up above the top plate of the wall, hugging the bottom of the trusses, meant our 4″ of Roxul Comfortboard 80 over the Zip sheathing would rise above the top of our walls, so that thermally we would be protected going from the exterior walls to the attic, which will be filled with 24″ of blown-in cellulose — making our thermal envelope continuous for the whole house: under the basement slab – exterior of foundation – exterior walls – attic (except for one small gap at the footing-slab-foundation wall connection, which I talk about in a separate post: Foundation Details).

A high R-value wall meets up with a high R-value attic, with no thermal bridging, making our thermal layers continuous. When this is combined with an equally air-tight structure, conditioned air cannot easily escape — resulting in a significantly lower energy demand for heating and cooling (and therefore lower utility bills), and added comfort for the occupants.

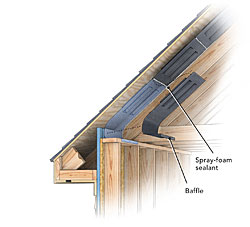

Here’s a nice illustration from Fine Homebuilding magazine showing a similar set-up:

I tried using rolls of conventional peel-and-stick window flashing membrane, purchased from Home Depot and Mendards, but they performed poorly, even in unseasonably warm temperatures for February in Chicago.

I then switched to Grace Ice and Water Shield, normally used as a roofing underlayment along the first 3-6′ of roof edge.

Since it came on a long roll about 4′ wide, my wife and I cut it down to a series of strips that could more easily be applied to the wall-top plate connection.

While the sun was out, the Grace membrane worked fairly well, especially when pressure was applied with a J-Roller.

Unfortunately, the sun and warmer temperatures didn’t stick around long enough for me to finish.

When the weather went gray and cold again, we started to use a heat gun to warm up the Grace membrane, which had turned stiff and nearly useless in the cold.

After wasting a lot of time and effort trying to pre-heat the Grace membrane before installing it, I finally relented and switched to the much more expensive (but also much more effective) Extoseal Encors tape from Pro Clima. Where the Grace membrane lost virtually all of its stickiness, the Extoseal Encors stuck easily and consistently, with the J-Roller just helping it to lay flatter and more securely.

It was a case of trying to be penny wise but ending up pound foolish. Looking back, I would gladly pay an extra $300 in materials to have those hours of frustration back (including the time it took to run to the store and buy the heat gun, which turned out to be ineffective anyway).

After finishing sealing the Zip sheathing-top plate connection on all the outside perimeter walls over the weekend, it was time for the trusses to be installed.

Trusses

Zach asked me to stand by the front door rough opening and give the crane operator hand signals. It was a fun way to watch the roof take shape.

Once the trusses neared the front door, Zach could signal the crane operator himself, so I was able to get some shots from just outside the construction fence.

Once the trusses were on, and the guys had a chance to install the final top row of Zip sheathing (up to the bottom of the trusses on the exterior side of the wall), I could move inside to seal all the connections from the interior.

Top of Wall (Interior)

Because of the cold, the Grace membrane was beginning to lift at the edges in certain spots, so just to make sure it had a nice long-term seal, I went around the perimeter of the house and used a layer of Tescon Vana (3″ wide) tape to seal the edge of the Grace membrane.

The picture below shows all the connections involved: top of Zip sheathing meeting the roof trusses and the top plate of the outside wall:

Shingles

We had to wait for shingles for quite some time. First we had to fire our GC’s, and then I had to find a roofer and a plumber (to make penetrations through the roof before the shingles went on). But before the plumber could even start, I had to get the Intello installed on the ceiling. And even before that, I had to figure out the insulation baffles, which I’ll talk about in a separate post.

It took awhile to find a roofer since they would have to make three separate trips for a relatively small job. The first trip was just to set down the Grace Ice and Water Shield at the edges of the roof, along with a synthetic roof underlayment (the consensus was that typical roofing felt wouldn’t hold up to long term exposure). As it turned out, it took weeks before the plumbers made their penetrations through the roof sheathing (literally the day the roofers showed up — a long, horrible story in and of itself that I’ll save for later).

The second trip out was to install the shingles on the roof of the house, while the third trip to install shingles on the garage roof could only happen after the Roxul on the exterior of our Zip sheathing was installed (in order to make a proper sealed connection between the wall of the house and the garage roof).

There weren’t many roofers willing to work with our unique Passive House sequencing, but our roofer was kind enough to take it on.

Unfortunately, the day after the guys installed the Grace membrane and the synthetic underlayment, we had a cold, blustery day. Once the wind grabbed the Grace membrane, the membrane rolled up on itself, turning it into a real mess.

Because of our recent past bad experiences with general contractors, I just assumed I was on my own, so I spent a couple of hours putting down new layers of the Grace membrane. When Peterson roofing found out, they were shocked I did it myself, and assured me I could’ve called them and they would’ve come back out. We were so used to people not following through, that low expectations meant it didn’t even occur to me to call them.

We initially were going to use Certainteed’s Landmark TL shingle, which mimics a cedar shake shingle profile, but Armando from Midwest Roofing Supply in Schaumburg, Illinois was kind enough to take the time to walk me through the options available, and explained that because our roofline isn’t steep, only the neighbors from their second story windows would get to appreciate the effect. He recommended we save some money, while not giving up on quality or durability, and go with the Landmark Pro product.

The shingles went on quickly since we have a relatively small and simple roof. In addition to the aesthetic leap the shingles made on the appearance of the structure, it also meant I didn’t have to go around cleaning up the subfloor every time it rained.

Although the synthetic underlayment worked pretty well at keeping the rain out, if there was significant wind combined with rain, the water easily found its way under the underlayment where it could then drip and fall on the subflooring below — pretty depressing showing up to the job site after a hard rain knowing I was going to spend the first hour just cleaning up and looking for leaks.

After they cut the opening for the ridge vent, but before it was installed, I managed to get this shot from inside:

I am interested in why you did a double 2×6 or i think its a 2×6 ….could be a 2×4 standing vertically together on the top plate? Traditionally you just have a double top plate and then roof trust sit on that, so i curious as to what the extra height is doing!?

LikeLike

Hi Johnny,

The 2×6 is creating a dedicated service chase for mechanicals like electric and HVAC.

Here are some articles describing their function:

https://www.builderonline.com/building/mechanicals/how-to-protect-your-envelope-with-service-chases_o

https://www.greenbuildingadvisor.com/article/service-cavities-for-wiring-and-plumbing

https://foursevenfive.com/blog/the-service-cavity-making-airtight-construction-easy-2/

In our case we were planning to have both electric conduit and our 3″ Zehnder ComfoTubes running in this space. As things turned out, we only used the space for conduit for our ceiling lights. Instead of 2×6, we probably could’ve gotten away with 2×4’s on the the flat since our ceiling lights aren’t traditional can lights but modern LED surface mounts, which require only a standard junction box.

In Passive House (or even Pretty Good House), it’s common practice to utilize a service chase (sometimes even in walls) to help protect the air barrier as HVAC, electric, or plumbing gets installed. In theory it should also help protect the air barrier when any renovations or repairs occur in the future.

Thanks for checking out the blog!

LikeLike

Hi Eric,

Did you consider taping the roof sheathing seams before the roofer did his underlayment install? Pros or cons if so? Thanks!

LikeLike

Hello,

We didn’t consider taping the seams of the roof sheathing. To be honest, we thought the underlayment was going to go down a lot sooner than it did.

If we had it to do over, we’d likely opt for a system like Huber’s Zip sheathing panels, or the Forcefield product…

These systems help to ensure that a roof can be watertight as quickly as possible.

LikeLike